Founded in 2004, Sudisa, a family-owned business, is one of the leading foundries in the Eastern region of the country today. With superior engineering capabilities and unmatched quality that second to none, Sudisa caters to the needs of varied industries which include, Automobiles, Pipe Fittings, Railways, Earth Movers, and more.

The history of Sudisa recounts the life's work of its founder and attests to his core value - "Striving to build and maintain a strong company by supplying our customers with quality products and excellent service". Providing quality products and excellent services to customers for nearly 15 years has helped the business grow exponentially ever since inception. Sudisa takes pride in its commitment to its mission of delivering quality work and recognizes that continued success must be earned through the consistent improvement of its unparalleled products and excellent service.

We produce high precision Grey and Ductile Iron Components and have a wide range of products upto 150 kg catering to a variety of industries.

Over the last 15 years, one thing that has remained constant in Sudisa is change. The company has always transformed as an organization embracing change to cater to the growing demand of innovation in the industry. Given below are some of the game changing moments in our growth story.

Installed fully automated Robotics Line & increased the machining efficiency. Installed H.M.C NHP6300 (DOOSAN) to enhance the machine capacity & capability.

SAP was introduced to facilitate timely decision making, superior inventories management and eliminate data redundancies.

Installed an in-house machining facility which includes VMC, VTL, Auto Balancing & CMM.

The company installed new High Pressure Moulding Line DISA Flex 70 HS along with 2000 kg Quad Track Induction Furnace with an additional capacity of 2500 MT per month.

Installed ARPA 900 Moulding Line along with replacement of 500 kg induction furnace with 1500 kg Dual Track Induction Furnace and enhanced its Finished Casting capacity to 15000 MT.

The Company was certified as ISO/TS 16949:2009.

The Company installed ARPA 600 Moulding Line along with 1000 Kg Medium Frequency Furnace and enhanced its Finished Casting capacity to 8000 MT.

Modification of Infrastructure with 500 kg Induction Furnace, ARPA 450 Moulding Line with semi-automatic Sand Plant.

Sudisa Family took over the company, with minimum modification and increased its annual capacity to 1800 MT.

We take pride in serving industries and businesses across the country.

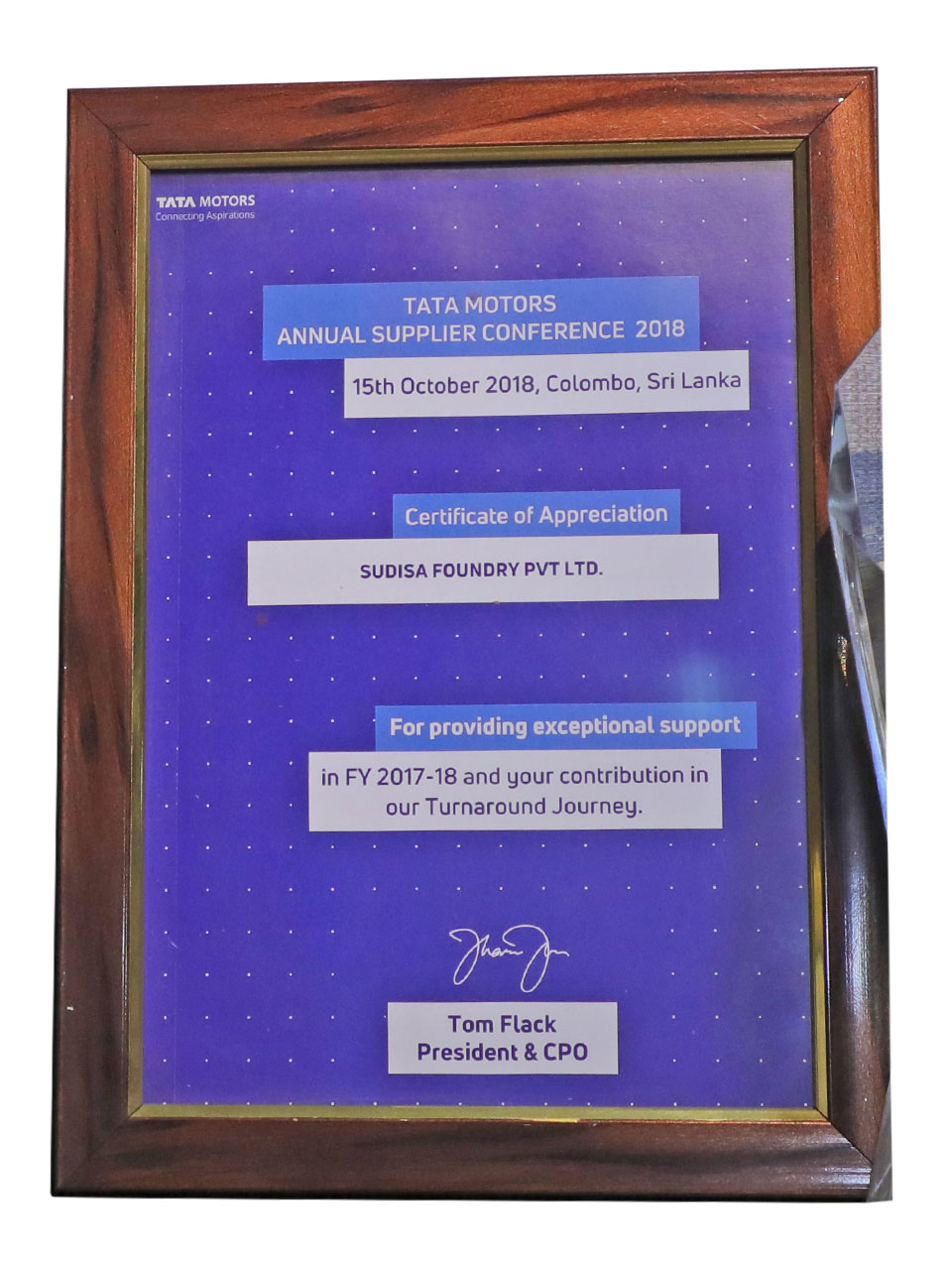

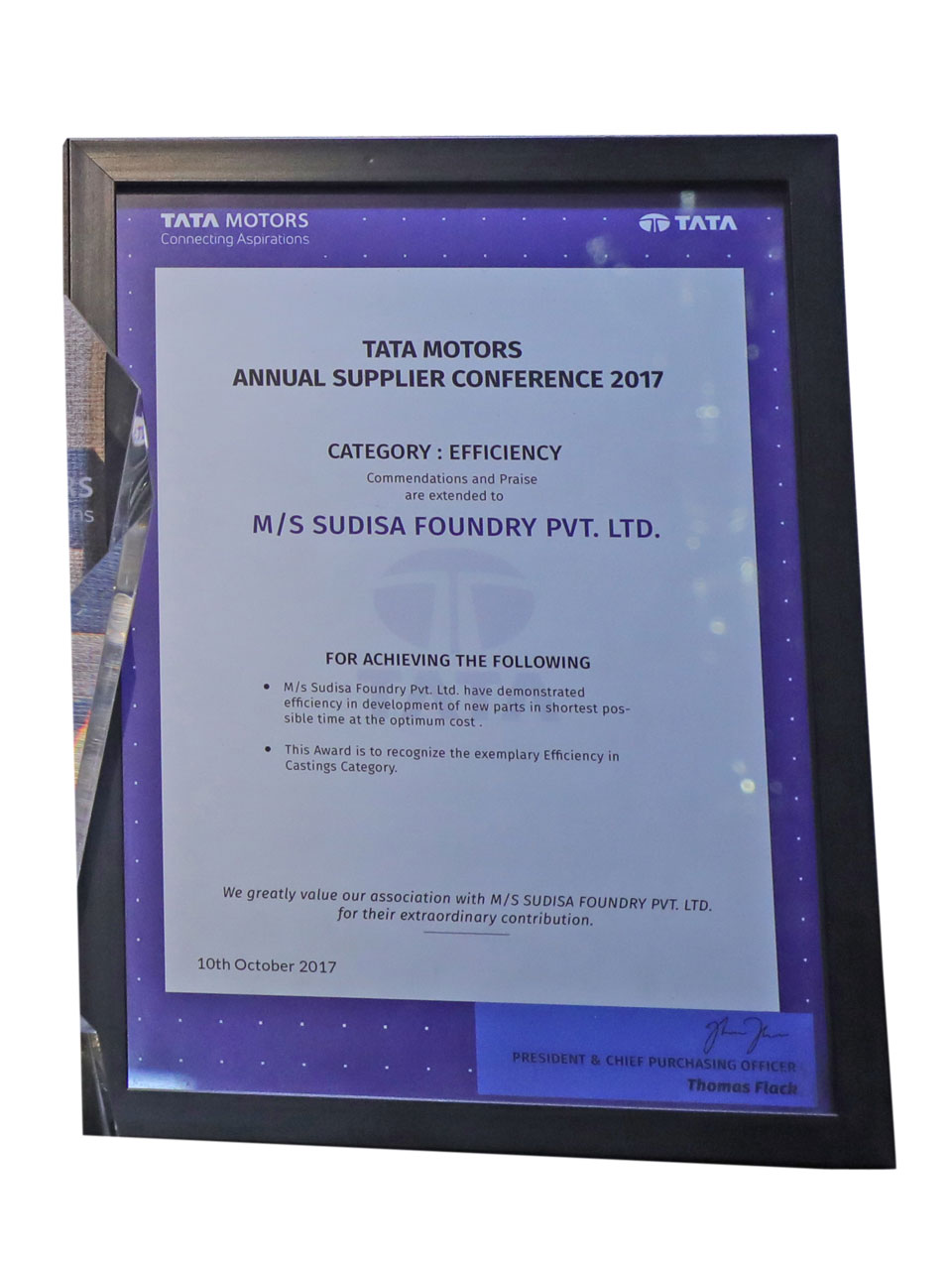

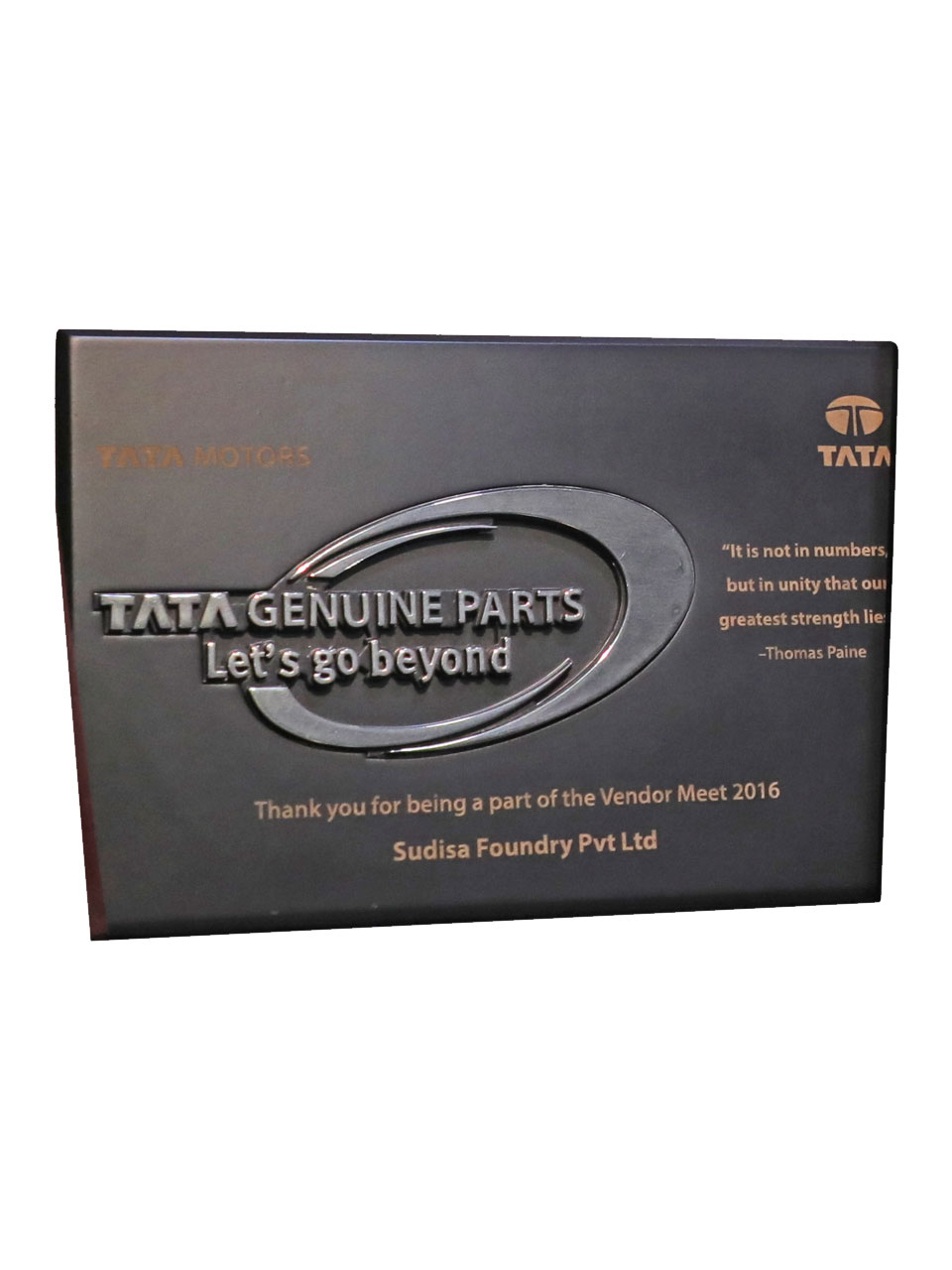

The exceptional competence and uncompromising dedication have been recognised by all major certification bodies. They stand proof of its sheer excellence and passionate efforts.