Sudisa is committed to produce services that meet the exact requirement of the customers, to provide products that conforms to the needs of the industry and customer expectations, every time. So, the company promises to monitor every single detail. The testing facilities have been thoughtfully planned and devised to ensure uncompromised quality and precision.

- Permeability tester

- Sand Rammer

- Quick Moisture teller

- Electronic Balance

- Sand siever

- Compactibility Tester

- Clay Washer

- Mould/ Core hardness tester

- Portable hardness tester

- Wet Tensile Tester

- Methylene Blue Tester

- Laboratory Oven

- Hot plate

- Sand mouldablity / Compatiblity tester

- Sand muller for preparing test samples

- Universal strength Machine for Green Compressive Strength and shear Strength

Detect 29 elements plus Carbon equivalent of test samples

Image Analyzer to check microstructures of samples

Every size of the ZEISS CONTURA G2 comes with a maximized measuring range. This guarantees measuring accuracy into the corners.

Universal testing machine with Graphical recording facilities for conducting tensile test.

The pendulum impact tester is a kind of impact tester, and is a detector for determining the performance of a metal material against impact under dynamic load, thereby judging the quality condition of the material under dynamic load.

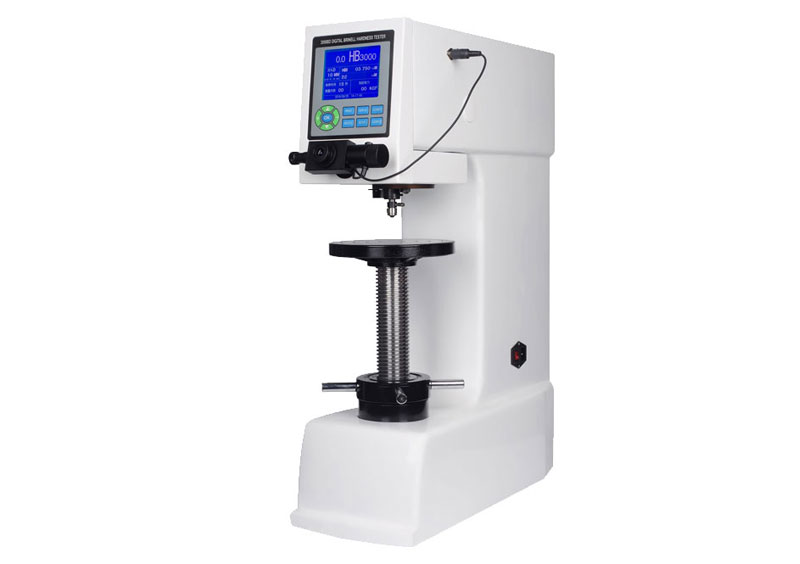

Twin screw & optical brinell hardness machine to check hardness of casting in BHN

Tensile Testing of miniature test bar with graphical recording facilities

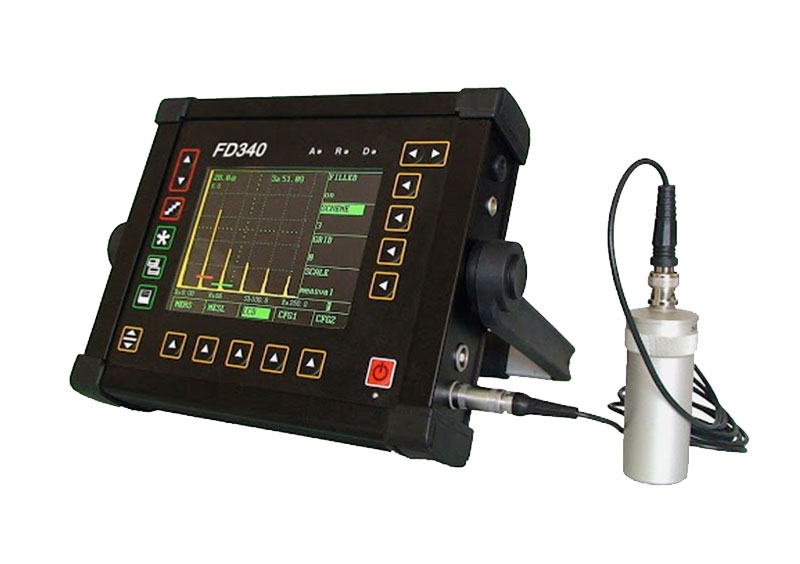

Ultrasonic Testing is a method of detecting flaw in casting of desired depth

Magnetic Particle Inspection is a process of detecting crack on surface and sub surface of casting within 6 mm depth.